As mentioned, here is the process used to get the lathe off the trailer and into my shop! I type this as I sit relaxing after a busy Christmas day/gig season with a nice glass of bourbon in one hand and a nice extended celebration of my wife’s Christmas Eve birthday (Happy Birthday, Emily, thank you for putting up with me.)

On to the unloading! As mentioned before, Tim (machinist friend) helped me go up to Canton, NC to pick up the lathe and did most of the rigging. I invited a former student and friend of mine, Craig, to come over and help unload the lathe. (He had mentioned wanted to make something on it, so I figured we might be able to take care of that right away. No dice. He did get to meet Tim.

Once arriving in my driveway, backing in the trailer was easy enough, but we had to content with a brick sidewalk and a 2″ high threshold into my shop with a 34″ door. Luckily (sort of) we have a very large 4-way poplar tree right next to the driveway. (I’ll likely post a blog in the future when that thing gets taken down.) This tree was perfectly placed to rig up a come along and pull the lathe out of the trailer on it’s 2×4 skids, carefully and slowly, until I could simply drive the trailer out from under it. We rolled it right onto the dollies, turned it around, and started for the shop door.

Boring, right? Well, to end this short post, we used rolling pipes and a floor jack to get the lathe headstock in first and situated into the shop correctly. Only scary moment of the whole day was when the lathe decided to come off the floor jack, which luckily was only a 1″ drop and the jack hit the motor. Motor is fine, and still worked before I started to replace it.

Lathe was nearly level where it sat and was easy to adjust using the adjusting screws on the lathe. I moved it about the width of 2 dollar bills to make it perfectly level.

Some pictures from the day:

Tim working on the rigging. We used the tree to the left to pull it out after straightening the trailer out. The shop door is open in the background.

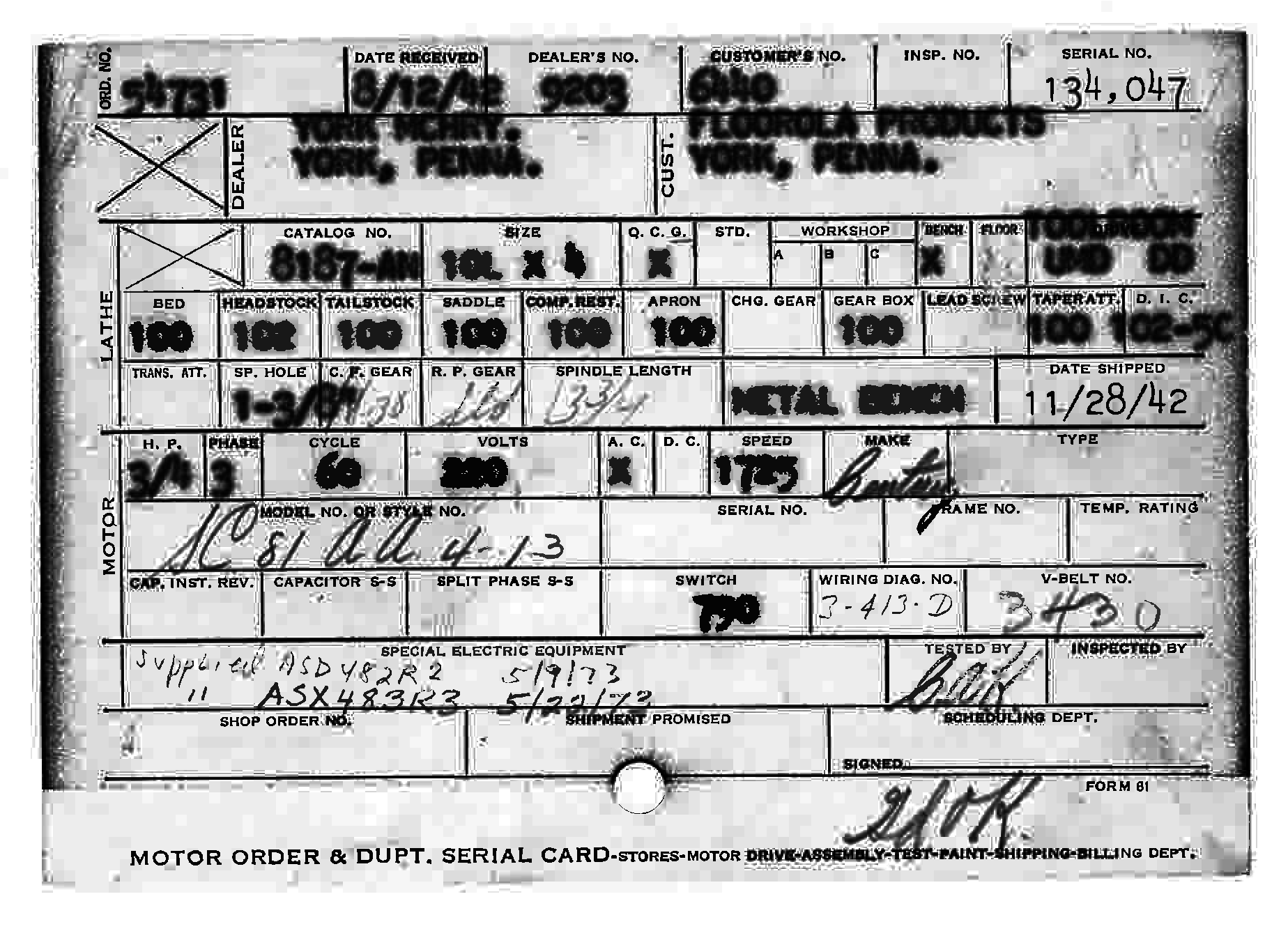

This post bores me… But I said I’d make it happen. My next post is going to be about my continued adventure with VFD and electronics on the lathe. I’ve also been passively researching the past of this lathe. Check this out:

This lathe was purchased by “Floorola Products” in York, PA. I’ll post my research later, but this lathe was used to make some parts for anti-aircraft guns. How cool is that?

DK

Leave a Reply