Spent a better part of my day today working on getting my 1943 South Bend “Heavy 10” lathe properly installed into my workshop. The to do is pretty long, but so far:

* Go get lathe and safely get home

* Get 1000lbs lathe into shop space

* Redo shop space

* Level the lathe

* Repair cabinet

* Work on VFD motor

Things I still need to do:

* Install new VFD motor and v-belt

* Replace felt “wipers” and oil them

* Replace old leather flat belt

* Add Digital Readout “DRO”

* Make a milling attachment and buy tooling for that

I’m enjoying my work so far and have actually used the lathe to get the shop space setup better and repair the lathe itself. Long story short, I need a 90 degree elbow joint for my air compressor and couldn’t find one. Solution? Buy a T-joint and make a plug for one end on the lathe! Easy as pie. The other quick job on the lathe was to make a knob for the motor cabinet for easier access to the belts.

Machining the knurled knob.

Knob installed! Simple job with a 3/8-16 thread on the other side. I may add a magnet or door locking plate on the other side in the future. We’ll see…

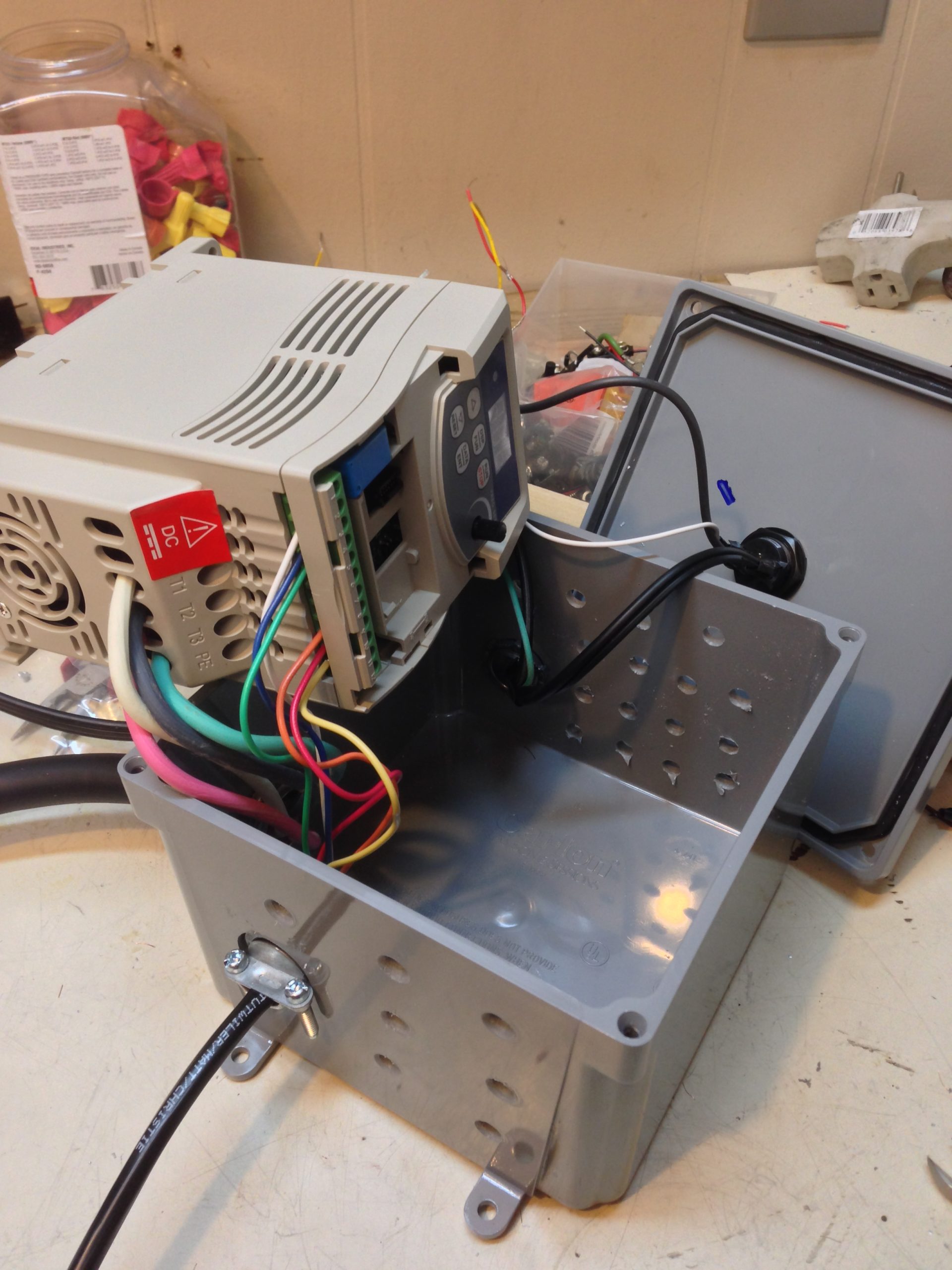

Knob and then the speed control and power box addition.

A majority of my time spent in the shop was learning how to use and program the “Variable Frequency Drive” for the new 3 phase 1 horsepower motor I bought to power the lathe. The older motor on the lathe works perfectly fine, but it’s not variable speed! As I have a lot of experience building and working on variable speed motors for vibraphones, this isn’t completely foreign to me. However, the voltages and foreign languages in the instruction manual are. So needless to say, I was careful about what I did!

“Test mode” to figure out VFD parameters. Most everything was easy enough (eventually) to figure out.

One parameter did trip me up though. I was having issues with starting the motor – it was turning, slowly, and stuck on the 3.8-4.2 Hz range. (US electrical systems run on 60 Hz, VFD allows a user to control that, thus controlling the speed.) Turns out, for those of you reading this with interest in the Teco EV series VFDs, Function 46, “Motor rated power” wasn’t set correctly to 1.0, but rather 0.8. Simple fix, harder to figure out.

See this link: http://www.owwm.org/viewtopic.php?f=82&t=156128

All buttoned up! The power button controls the VFD, which has a separate forward/off/reverse switch next to the speed control knob on the lathe.

I’m surprised you read this far… I plan to make a few more posts, for instance, one about actually getting the lathe and meeting the previous owner, another about finishing up this VFD install, and finally (hopefully) a post about the WWII connection this lathe has. I’ve ordered the serial number information from South Bend (now Grizzly Tools.)

Leave a Reply