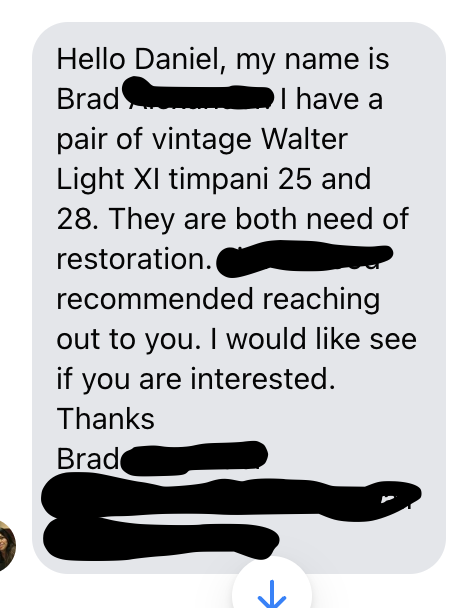

It started with an Facebook message…

…followed by a lengthy email conversation. Eventually it was agreed upon that I would buy these drums so that I could restore them to their former glory on my own time.

The timpani had survived a saltwater flood back in 1985; Hurricane Gloria. 38 years, these drums have sat unused and corroding away. It seems that they are stable for now and my plans will start with a pressure washing to remove all the chipping paint. I can farther strip things when they’re apart. More on that later…

June 14, 5:45am, I pulled out of my driveway in Greenville, SC with the goal to meet Brad for lunch at 1 o’clock or so at a place halfway between the two of us. That just happened to be Clermont, KY, land of my favorite bourbon, Knob Creek. We found a nice lunch spot (Isaac’s Cafe) that is part of the Bernheim Arboretum (both highly recommended!) After driving for about five hours on the interstates and 2 hours through the beautiful countryside of Kentucky, Brad and I both arrived at the same time.

After having shared lunch and swapping stories, we headed back to our vehicles and moved the timpani from his car to my “DAN VAN,” flaking paint and all. Brad is a composer and shared some compositions with me, one of which I’m hoping to work up and record sometime in the near future.

If I’m being honest, I spent a lot of time thinking about this trip, planning ahead, looking forward to getting the timpani. What I looked forward to the most, however, was the Jim Beam Distillery tour (where Knob Creek is made). Immediately after getting the timpani, I head across the road to the distillery, checked in, and enjoyed an informative tour and tasting.

I found my favorite pour, Knob Creek 12yr, in the gift shop, along with a single barrel I got to see bottled on the line. Now I’ve tried all the (known to me) variants except for the 18yr. With my purchases, I headed out to Elizabethtown, KY where I had a “pub stay” Airbnb waiting for me, along with a gift card for dinner downstairs at Wicked Eyed Woman. Dinner was fantastic, but to top it off, I was able to get a glass of the 18yr (for a killer deal, too). It seemed appropriate and timely, and a great way to end my day…

But my day wasn’t done! After heading back to my apartment, I found a brewery two blocks down the road and headed that way. Immediately upon walking in the bartender was very nice, suggested various brews, and we chatted about why I was in town. I also made some friends at the bar and we chatted/drank past closing time. It was a nice way to end the successful day: safe travels, good lunch with a new friend, timpani, bourbon, dinner, beer with new friends… these are a few of my favorite things! (My wife is convinced I could converse with a brick wall, and I take that as a compliment.)

Next day… hangover. Of course. But around the corner from my Airbnb was a nice coffee shop (Vibe Coffee), which helped a little bit. The two liters of Smartwater that I bought from the gas station on the way out was likely the key to making it the rest of the day! Goal for the day: no interstates.

The drive was pretty, and relaxing. The timpani (and bourbon) were secured, and the only thing on my mind was making it home safely. The day was uneventful, but some neat sights were seen. Hot Springs, NC looked like a neat little Application Trail pass-through. 25E is an interesting drive, and 251 (wherever that was) was “wild.” It followed directly along the French Broad River. That was some of the prettiest driving of the day.

Once home (Thursday night), I about collapsed. Friday rolled around and I took the timpani over to Tim’s shop for him to have a look. I plan to use a pressure washer to blast the loose paint off, along with some of the white powder that has seeped out of the aluminum castings. I’m concerned about the casting integrity, but nobody else seems worried that I’ve talked to. I’ll likely get them vapor or soda blasted before doing much of anything to them.

Speaking of plans, here are my initial goals for the “Flood Lights,” prior to a thorough inspection.

- Pressure wash the timpani as-is. I’m not worried about rust, because they’ve been rusted already for so long. (Already done. See pic.)

- Loosen everything with penetrating oil. I know the 28″ has a stuck piston, which is Al on Al. (Process started at time of publishing.) Timpani in storage for “the soaking.”

- Disassemble enough to inspect parts closely, but hopefully leave the struts attached to the base and ring.

- Free up the seized 28″ central piston, or otherwise bore it out and replace it.

- Wash the timpani bowls and hopefully maintain the patina. If not, I may just strip them entirely and let them patina naturally, again. They’re in good shape from initial look-see.

- Remove ears from hoops, marking as I go, and hopefully getting them refurbished/replated, and convert the ears to screws instead of rivets. If the rings aren’t round, attempts will be made to save them before replacing. If replaced, I’ll size them up one inch (from 2700 to 2800, 3000 to 3100.)

- Check the alignment of the frames and roundness of the suspension hoop. If all is good, leave it alone and paint it! (Or powder coat AND then paint. I think it’ll help maintain the castings from further corrosion.)

- Check all parts and make a list of what needs replacing, fixing, or modifications. All will need refinishing.

- Upgrades planned: set screw on the ratchet mount, ball bearings on the cam follower.

- Possibly update the gauges. However, I might leave them as they are, but cleaned up and with engraved indicators. (Custom.)

- Drill struts for gauges and boss for hanger arm to convert to German, if wanted by future owners.

- Basically, at cover value, this could be as simple as a deep cleaning, replating, polishing, etc, but I think there will be a few hidden “gems” of issues in the drums worth fixing. But the 25″ actually sounds pretty good (and they both have the original heads!)

- Overall goal: restoration (not rebuilding like I’m doing on the ’57 pair) and sale!

So at publishing, I’ve power washed the timpani and removed all the loose paint and aluminum hydroxide (or oxide?) from the exposed spots. They then got a bath in PB Blaster to help free up some stuck parts. The aluminum tension rods into the steel barrel nuts actually came free (15/16 of them anyway) fairly easily. I’ll slowly work loose all the fasteners and hope I can actually free up everything on the drums without damaging anything. However… I’m prepared to remake parts as needed, but I’d like to salvage the castings as they are! They’re aluminum, so if I need to weld-repair them, I’ll try my hand at MIG welding aluminum before taking them to the pro for some TIG welding.

Right now I see them as non-functional instruments, but for a while, they’ll be broken down and treated as machines, and eventually be brought back to their former glory as top of the line instruments. Some of this may make it to YouTube, but I will certainly try to keep the blog updated with the progress. I’m mostly writing this stream-of-conscience so that I don’t forget it! I know some folks would rather read and see than to watch, so this one’s for you.

Included below is a large gallery of many of the photos I took throughout my trip and during pressure washing. If you have questions, leave them in the comment section. I think you can subscribe here to be notified whenever I post within this blog, otherwise follow DK Percussion on Facebook! Cheers!

Leave a Reply